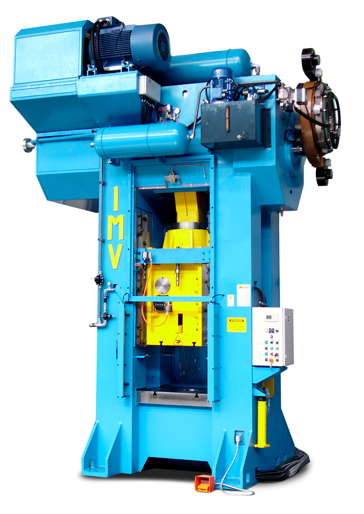

Mechanical presses

OUR STANDARD IS YOUR CUSTOMISATION

The competence and experience of our design engineers, combined with the use of sophisticated software programs, in some cases developed ad hoc, allow the utmost freedom of customisation, both mechanical and in the application of different technical solutions. Parametric design, 3D modelling and F.E.M. tests are just some of the most advanced processes used for the design phase. This is supplemented by a longstanding experience acquired directly in the field for more than eighty years now. The choice of the right rated energy in relation to the production frequency is a crucial piece of information to be taken into account when configuring the press, in order to be able to use the dies in the best possible way. Based on the requested energy, the type of lever mechanism, the press dimensions and automation, I.M.V. PRESSE offers different transmission combinations.

PRESSES FOR SHEET METAL FORMING

Over eighty years of experience in sheet metal formingh. I.M.V. manufactures presses from 100 to 3500 tons, with bolsters up to 7 meters, with one, two or four pressure points, with eccentric or equipped with different types of slowing motion with levers or with servomotor. The commonly processable materials are steel with high elastic limit, high resistance, aluminum, stainless steel, pre-painted and galvanized. The sectors of application are the most varied, from the automotive to the home appliance, household goods, construction and components in general.

Presses for deformation and hot molding

Normally used in sectors such as automotive and aeronautics, these presses are used, according to the model, for the crushing of billets, for the molding or for the deburring of pieces already stamped. Depending on the needs, more presses can be supplied or combined with screw presses.

Sizing presses for pauda

Normally used in the automotive sector, they are presses equipped with different mechanical and hydraulic movements that are synchronized in different ways and act on a mold holder in which the user inserts the matrices necessary for the parts to be produced. These presses, according to the preparation, can be used to compact the powder or to calibrate the pre-compacted piece after the heat treatment.